On June 15, the Pingxi Station of Shenzhen Metro Line 3 Phase IV Project undertaken by China Railway 14th Bureau Group Corporation Limited completed the assembly of the fifth ring component, marking the successful application of China's first fully-assembled metro station assembly process and equipment jointly developed by China Railway Science and Industry Group Co., Ltd. under CRHIC and Guangzhou Metro Design & Research Institute Shenzhen Branch and the change sets for metro station construction technology.

The assembled station splits the main structure of the station into many modules, which are prefabricated in factory and then transport to construction site to construct station the same way as 'building blocks'.

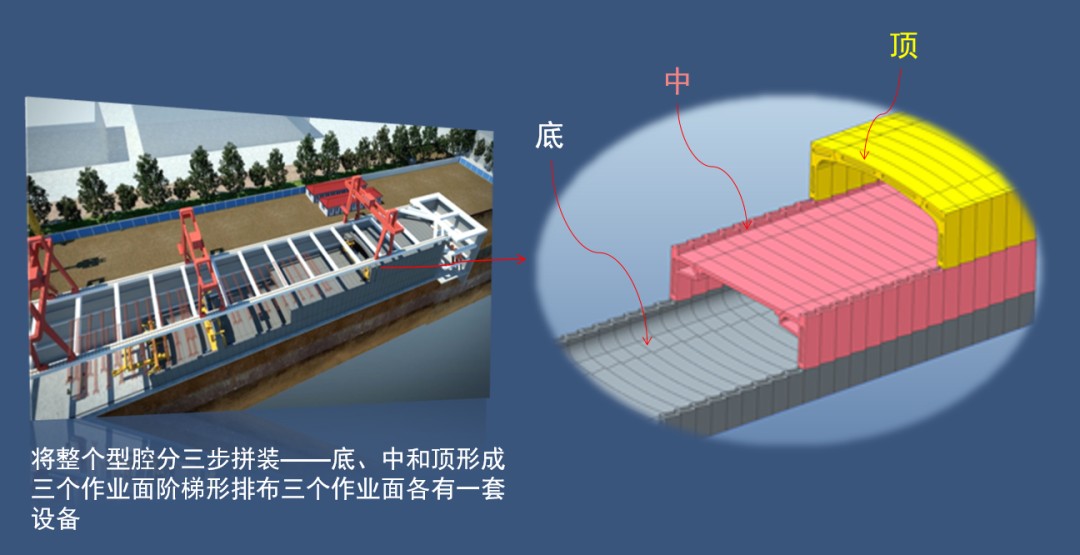

This assembled station construction equipment initiates a mode featuring ladder distribution of three working faces and synchronous construction by three assembly machines. The three assembly machines assemble module prefabricated parts one by one according to the top, middle and bottom layers. The single prefabricated component is light to be freely transported in the city. With the aid of GPS high-precision positioning system during installation, the equipment allows for accurate, flexible, efficient and safe assembly and adjustment of prefabricated components. The metro station construction method is thus innovated.

Pingxi Station is a two-story underground island station, measuring 222m long, 20.84m wide in the standard section and 19.2m deep. It is China's first fully-assembled station using an internal support system. Circumferentially, the Station is locked by steel members shaped as 'C+H+C', and longitudinally, rings are locked by ball head lock (similar to 'nut and screw') connectors. Compared with traditional cast-in-place construction method, the fully-assembled construction method applied by China Railway Science and Industry Group Co., Ltd. has reduced the manpower input by 80% and improved the efficiency by more than 200 percent. It allows to greatly enhance the construction efficiency, eliminate the construction risk, save the steel consumption, and substantially reduce the construction waste pursuant to the environmental protection trend.