On July 20, China's 600km/h high-speed maglev traffic system rolls off the production line in Qingdao, Shandong Province. China Railway Baoji Bridge Group Co., Ltd. (CRBG) affiliated to CRHIC undertakes its turnout design, manufacture, installation and debugging.

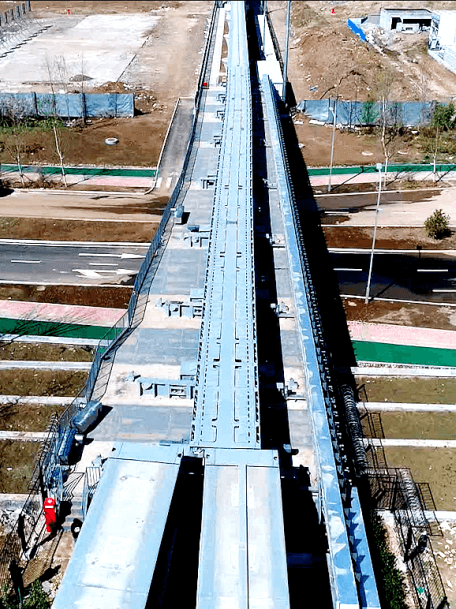

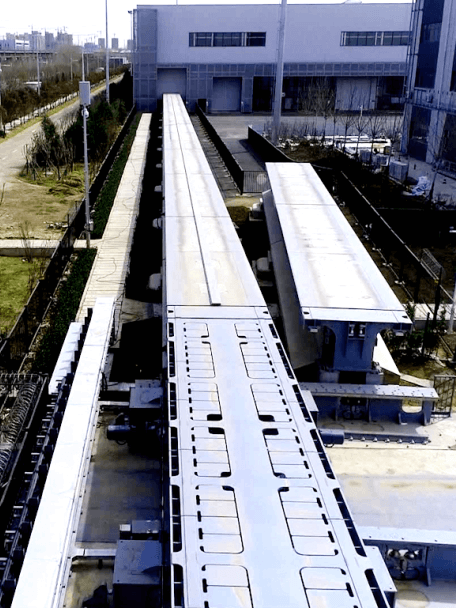

The maglev turnout system manufactured by CRBG is a flexible right-hand turnout, with a length of 78.432m, width of nearly 2.8m, switch distance of 3.65m and straight passing speed of 600km / h. It is the world's highest passing speed maglev turnout. During the field debugging, the Project Team of CRBG continuously optimized the timing sequence of each driving point and the driving collaborative system of each dynamic point of the turnout to ensure the optimal state of the stress, alignment and driving force of the turnout beam, and the switch stability and smooth alignment, to the greatest extent.

The turnouts occupy the leading position in the industry in terms of main parameters. During its development, CRBG developed an intelligent control system to minimize the bending stress of beam in the switch process, and designed the eight span continuous flexible turnout with large stiffness to ensure high-speed maglev train may pass through. During its manufacture, CRBG applied precision group welding and integral machining technology to guarantee the precision of turnout beam, made proprietary tooling to allow overall flip of ultra-long, ultra-heavy, flexible turnout beam structure parts, adopted overall turnout static assembly technology to simulate the requirements of the line rail transit, bringing valuable experience for future construction of 600km/h high-speed maglev line.