For present shaft projects available in capital construction, the construction problems include difficult operation, poor environment, high labor intensity and high risk. Thus a new shaft construction technology that is safe and efficient is badly needed. 'The idea of full cross-section tunnel boring machine needs to be applied to shaft boring machine for developing new products and new categories.' As pioneer and leader of China's tunnel boring machine industry, China Railway Engineering Equipment Group Co., Ltd. (CREG) under CRHIC has always been on the forefront of innovative TBM research and development, strategically aiming at this new field with an advanced vision.

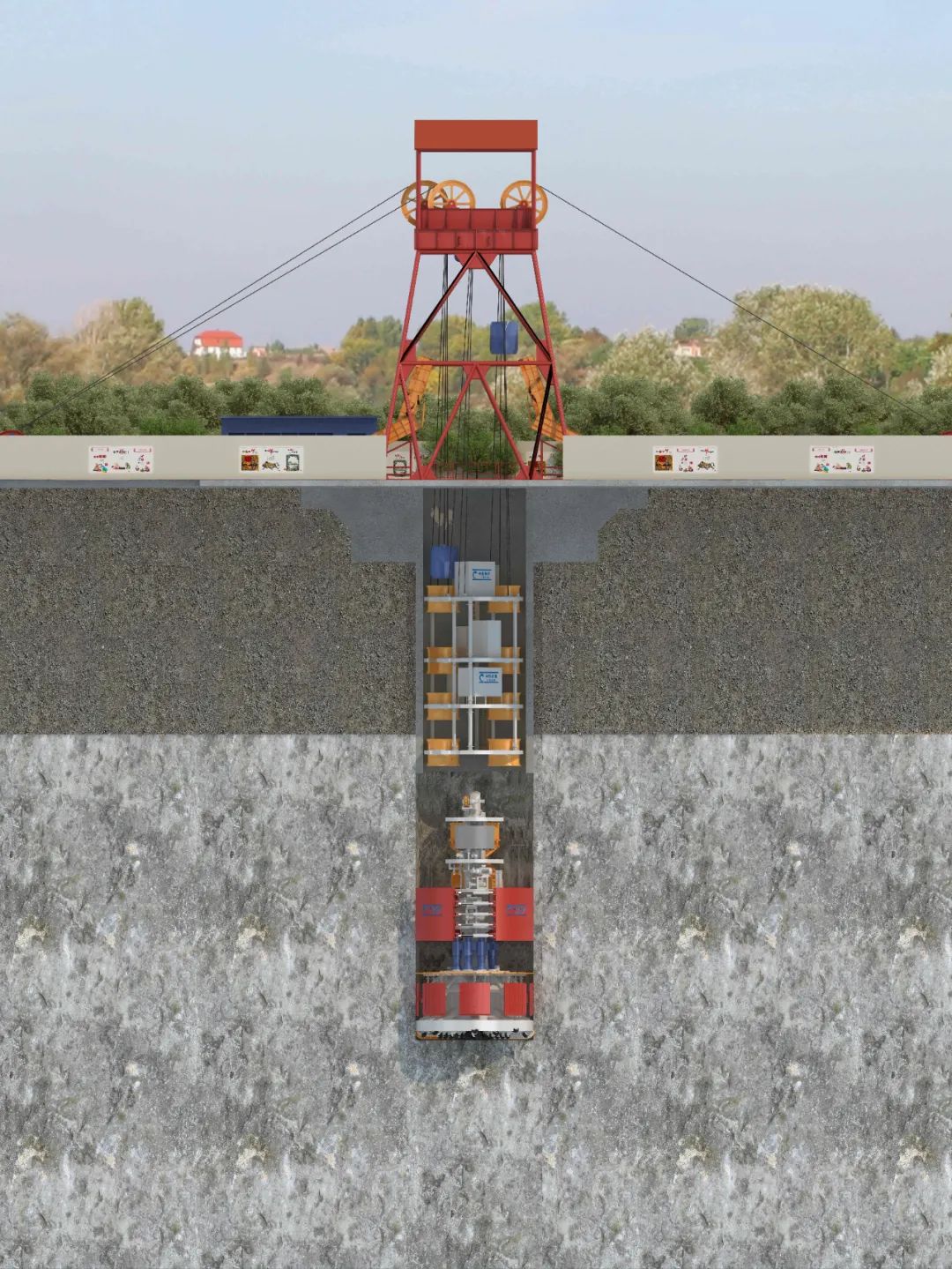

CREG, together with the project owner, has recently put full cross-section hard-rock shaft boring machine from an idea into reality at the construction site for a hydropower station in Ninghai County of Zhejiang Province. Consequently, they have successfully overcome the technical problems facing the world's full cross-section hard rock shaft boring machines, made down-shaft unmanned tunneling available for the first time, and made breakthrough in the field of shaft boring machine. The R&D team put most of their efforts on the following problems, such as the adaptability of equipment to variable strata, small space available for vertical construction working face, troubles in transporting muck and materials, and difficulty in handling groundwater.

Compared with traditional construction methods, the boring machine developed by CREG saves more than 50 percent of manpower input, but increases boring efficiency by more than 200 percent. With its features of unmanned down-shaft operation, automatic boring and on-ground remote control, the machine accumulates experience for future similar underground construction projects, and provides a new solution to full cross-section thousand-meter-long shaft boring.