'Gonggong' is 92 meters long and 13 meters wide, weighs 575 tons and has an effective span of 48 meters. With positioning system being used to drive piles, the equipment allows for all 'sky' operation covering lead hole, pile driving, beam erection and pier assembly. It is especially suitable for shallow lakes, marsh and wetland protected areas, prosperous urban areas and others where traditional construction methods are not allowed.

In June 2021, China Railway Science and Industry Group Co., Ltd. developed Chisha, China's first building component assembly robot. The robot is 80 meters long, weighs 120 tons, and has an effective span of 69 meters. Encased in a double truss main beam structure, it has eight 'legs' that can operate independently. Each leg can expand and contract independently, and travel horizontally and vertically to meet the strict construction demands of uneven steps, tower cranes and cast-in-place hollows. The robot is currently used for the construction of Chisha Depot of Guangzhou Metro Line 11.

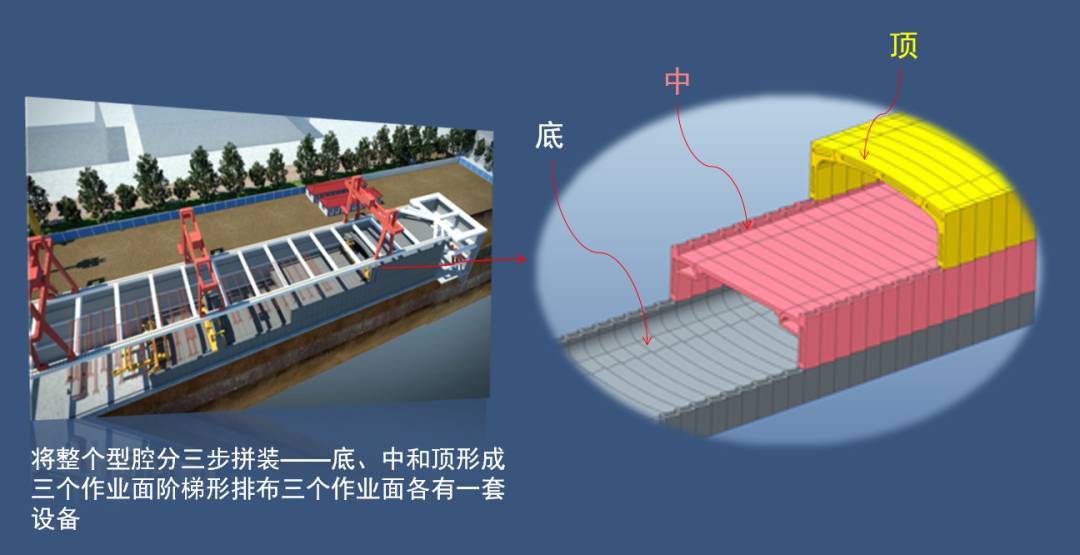

Along with the recent successful application of China’s first fully-assembled metro station assembly process and equipment jointly developed China Railway Science and Industry Group Co., Ltd. under CRHIC and other companies in Pingxi Station of Shenzhen Metro Line 3 Phase IV Project, metro station construction technology will see changes. This assembled station construction equipment initiates a mode featuring ladder distribution of three working faces and synchronous construction by three assembly machines. The three assembly machines assemble module prefabricated parts one by one according to the top, middle and bottom layers. The Single prefabricated component is light to be freely transported in the city. With the aid of GPS high-precision positioning system during installation, the equipment allows for accurate, flexible, efficient and safe assembly and adjustment of prefabricated components. Compared with traditional cast-in-place construction method, the fully-assembled construction method has reduced the manpower input by 80% and improved the efficiency by more than 200 percent. It allows to greatly enhance the construction efficiency, eliminate the construction risk, save the steel consumption, and substantially reduce the construction waste pursuant to the environmental protection trend. It is expected to have extensive application in the future.