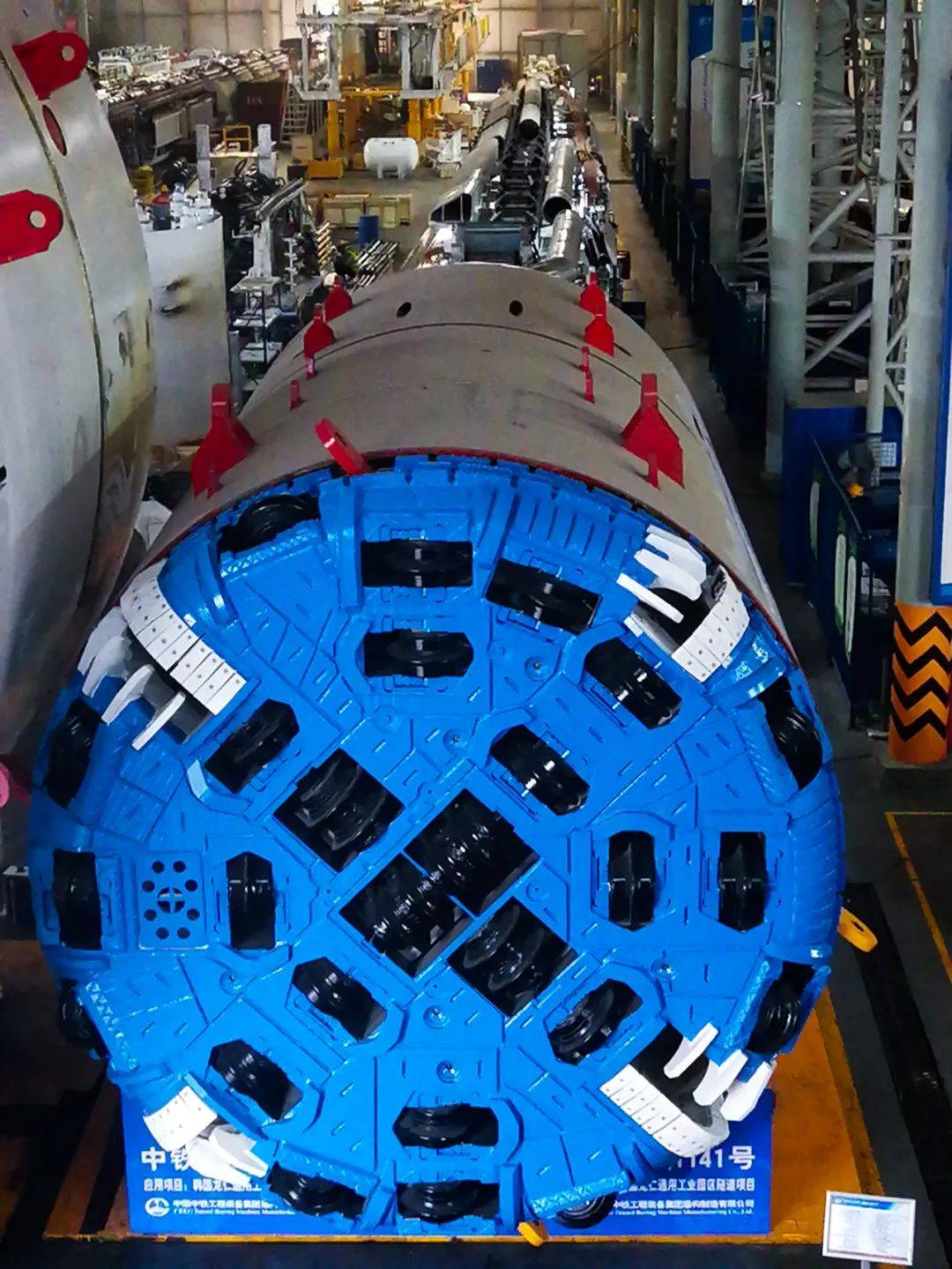

Recently, the earth pressure balance TBM 'CREC 1079' developed by China Railway Engineering Equipment Group Co., Ltd. (CREG) under CRHIC and applied to the Sylvan Drainage Tunnel Project in Diyarbakir, central Turkey, and the single shield TBM 'CREC 1141' applied to the cable tunnel project in Yongin Semiconductor Industrial Park in South Korea rolled off production line.

The Sylvan Drainage Tunnel has a length of 13.23km, maximum burial depth of 400m, and excessively high gas concentration. Also the survey reveals a fault on the way of excavation, leading to collapse risk and harsh geological conditions. In order to adapt to the project characteristics, the machine reinforces its fire resistance, explosion prevention and stability design, and adopts tailored design in selection of refractory materials, explosion prevention of key parts, fire prevention and cooling of equipment, ensuring safe excavation in such long distance stratum with large burial depth and high gas concentration. It is the largest diameter EPB TBM exported from China to Turkey.

In the cable tunnel project in South Korea's Yongin Semiconductor Industrial Park, the tunnel constructed by TBM has a length of 5,183m, and consists of three sections constructed by three single shield TBMs developed by CREG. This tunnel section is 2,119m long, has a maximum buried depth of 175m, mainly contains gneiss with maximum rock strength being 208.9 MPa and high abrasion, and passes through fracture zone and Ssangji River along the way. Given the project characteristics, the R&D team tailored TBM 'CREC 1141'. The machine innovatively adopted waterproof design for the single shield TBM, and configured STS system with the company's independent intellectual property rights, which provides customers with real-time tunneling information and responds to the challenges brought by construction environment in a better and more comprehensive manner.