The new Slussen bridge will soon arrive in Stockholm, after traveling 20,333 kilometers from China. This journey enables aproject that will benefit Stockholmers for more than a century.

At the center of Stockholm is Slussen, a transportation hub that more than 450,000 people pass through daily. Yet Slussen is more. It’s also a lock that protects Stockholm’s drinking water supply and it serves as a meeting point in the central city.

With so much happening at Slussen, it’s a place full of motion, especially now: this 80-year-old infrastructure is worn out and undersized for future needs, so it’s being replaced in one of Sweden’s largest construction projects. Each day, an assemblage of cranes, trucks and hundreds of workers build toward a new, better Slussen, with all activities carefully planned to disturb the life of the city as little as possible.

Yet perhaps the most motion with Slussen is not in Stockholm but rather is on a ship. The new Slussen bridge was built in China and is being transported in one gigantic piece to Stockholm. This140-meter-long, 3,500-tonne package is expected to arrive in Stockholm in March. Then through a carefully controlled sequence of activities, it will be guided into its new position, connecting Stockholm’s Old Town with its southern island of Södermalm. Once in place, this bridge is not meant to move for at least 120 years.

The new steel bridge has been on the seas since January 2. This ambassador of Stockholm will travel 20,333 kilometers, passing off India’s southern tip, through the Suez Canal, across the Mediterranean Sea and through the English Channel and the Baltic Sea. It’s been a challenging journey, as tough weather conditions meant the ship, the Zhen Hua33, had to remain anchored off Spain and Portugal to await calmer waters.(Follow the ship’s progress on this ship tracking website.)

Careful coordination

That the bridge was produced in China was due to the specialized nature of the manufacturing and the qualifications and availability of relevant global suppliers.

“There are not many suppliers who can manufacture a steel bridge with this size and complexity,” says Mats Strindevall, head of steel unit. “Together with the City of Stockholm, we decided that the bridge would be manufactured in one piece.”

To manufacture the bridge, contacted several suppliers, mainly from Europe and China. We thoroughly evaluated qualified suppliers before the bidding process began. This process included visits to these companies’ facilities and conducting audits of their performance with working conditions, ethics and the environment.

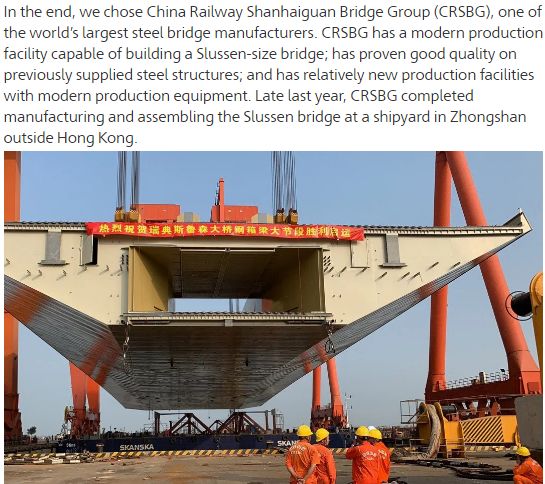

In the end, we chose China Railway Shan haiguan Bridge Group (A subsidiary of CRHIC), one of the world’s largest steel bridge manufacturers. CRSBG has a modern production facility capable of building a Slussen-size bridge; has proven good quality on previously supplied steel structures; and has relatively new production facilities with modern production equipment. Late last year, CRSBG completed manufacturing and assembling the Slussen bridge at a shipyard in Zhongshan outside Hong Kong.

Coordinating the manufacturing of the bridge in China with the simultaneous construction of its concrete support structure in Stockholm has been among the project’s biggest challenges, says David Karlsson, production manager for the bridge project. The team focused on overcoming challenges relating to distance, languages and ways of working, ensuring careful coordination of the work.

Exciting journey

“Extremely well!” says a smiling David Karlsson. “I have been therein China and gotten to know this bridge, so I know what is coming. When you stand next to the bridge and you are so incredibly small in comparison. It will be great when the bridge arrives and we can finally complete the work.”

The new bridge opens for use this fall, after it has been painted a distinctive golden color to harmonize with surrounding buildings. Pedestrians, cyclists and drivers will all find the bridge welcoming to them.