On April 25, CREC 872, the first TBM using domestic 3-meter level main bearing designed and manufactured by China Railway Engineering Equipment Group Co., Ltd. (CREG) under CRHIC, successfully completed the Gangtianlu Station-Jinjiayan Station double-track excavation task, the last shield interval of Suzhou Metro Line 6 Lot 10 Project, marking that China's first TBM applying domestic main bearing completed its excavation task in Suzhou.

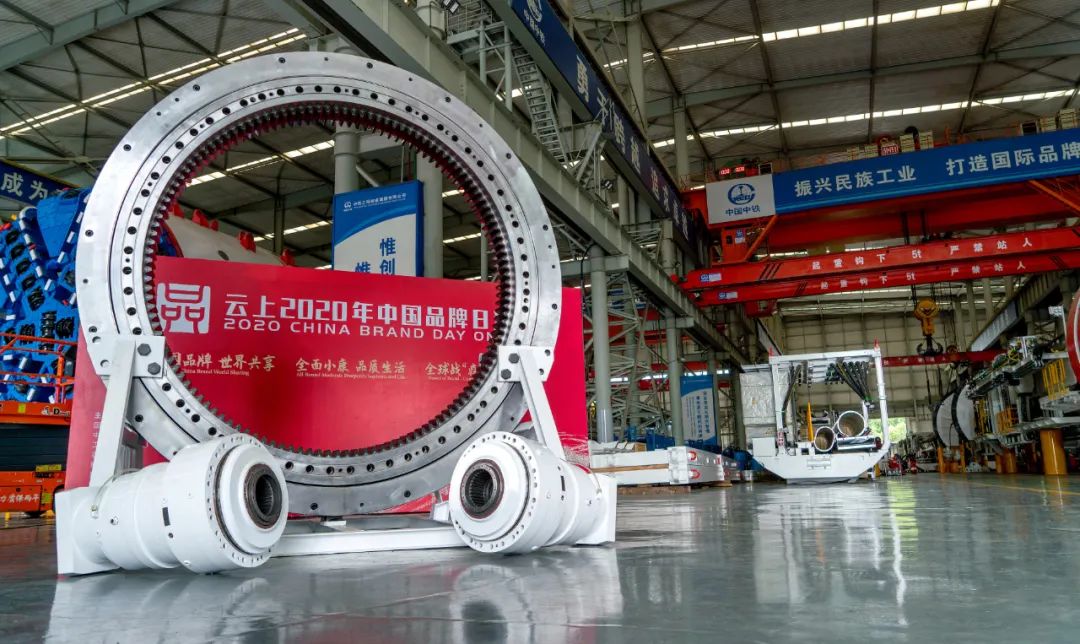

Main bearing is referred to as the 'heart' of a TBM. It drives the cutter head to rotate and cut the tunnel face, supports rotation of the cutter head, and bears the main load during the operation of TBM. It is a key component of the cutter head drive system. Since July 2015, CREG has successfully applied for the national foundation consolidation program for industrial transformation and upgrading together with domestic enterprises having technical advantages in main bearing and reducer, undertaken the construction project of industrial test platform for TBM main bearing and reducer, and attempted to eliminate difficulties in TBM's core key technologies. CREG finally made a breakthrough in the key design, materials and heat treatment, precision machining and detection technologies of TBM main bearings, and developed the first batch of home-made 3m-diameter main bearing for 6m-diameter conventional TBMs.

'CREC 872' has an excavation diameter of 6.83m, a main bearing diameter of 3.06m, an overall length about 85m, a total weight approximately 550t, and the maximum excavation speed of 0.1m/min. Its maximum daily performance is up to 18-19 rings, and the maximum monthly performance reaches 600m.